Aston University is one of the oldest and best respected places of further education in Birmingham. The campus sits in the heart of the UK’s second city, less than 10 minutes walk from the city centre. Aston University caters for around 7,500 students, studying more than 120 different undergraduate courses and more than 80 postgraduate courses. There are 1,200 staff and 18 buildings spread across the 200 acre site.

During the first half of 2001 Aston University drew up a plan to upgrade their network, including a proposal to replace the entire existing cabling infrastructure. The existing infrastructure was made up of cabling of different types (RS232, Cat 3, Cat 5 and coax) and qualities from a number of different manufacturers, most of which had no performance warranties. Mid 2002 the University went out to competitive tender for new telephony and data systems, including cabling, and Electron, through communications solutions and services provider Damovo, were one of more than 120 companies that initially responded. Electron were heavily involved throughout the tender process in drawing up the design of the cabling infrastructure, ultimately producing a proposal that maximised the coverage of the cabling whilst keeping costs within budget. The University knew that they could rely on the advice of Electron’s designers as they held the BICSI Registered Communications Distribution Designer (RCDD) qualification.

A Brand-Rex Cat 6 UTP cabling solution, complete with a 25 year performance warranty was selected. A decision was taken to install SMARTPatch panels and patch cords as it is intended that the university will implement a full intelligent patching solution in the future. A total of 55 wiring centres were necessary in order to provide the level of coverage required, many of which had to be newly created due to the lack of suitable existing facilities. The design of the main building, built around all 4 sides of a central courtyard, meant that up to 3 wiring centres were required on each floor in order that horizontal cable runs could be kept with the 90 metre limit.

During the course of 2004 Electron installed more than 6,000 Cat6plus UTP outlets in the 18 buildings across the university campus. At the peak of the work Electron had around 25 engineers on site, with the work being overseen by Electron’s Project Manager Simon Rhodes, in conjunction with the University’s project manager Dennis Mottram. Dennis commented “Electron worked very closely with the University, which created a great team that achieved a complex installation in a short time with minimal disruption. During this period we worked together to develop standards for design and installation. The team also working to CDM practises to reduce H&S risks.”

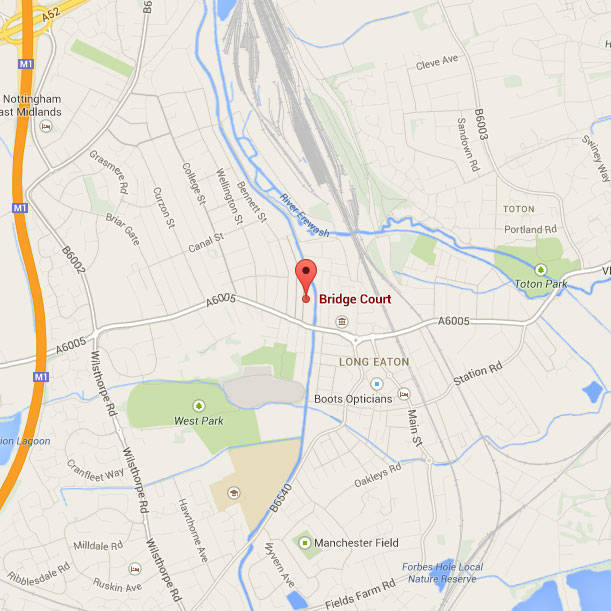

The length and size of the project necessitated that Electron had their own Portakabin on site to act as site office. However, storage space was extremely limited, meaning that schedules of deliveries from suppliers such as Mayflex had to be tightly controlled by team leaders. One of the principal benefits of using Mayflex was that their warehouse is only about 1 mile from the university, meaning that materials could be delivered or collected at very short notice.

Wherever possible Chatsworth open racks were installed in the wiring centres as these offered the most efficient use of space whilst maximising the patch cord management and minimising the requirement for heat management. Typically the racks were installed in threes, one being used for the active equipment and the other two for horizontal cable terminations. Each of the ports on the 260 installed Cisco edge switches was replicated on a port-for-port basis on Cat 6 UTP SMARTPatch panels in order to provide a higher degree of manageability when full intelligent patching is implemented.

The wiring centres were linked via four network nodes by more than 25km of OM3 and OS1 fibre optic cables, the singlemode cables being used where runs exceeded 550 metres in order to ensure future support of 10 Gigabit Ethernet. This comprehensive fibre backbone created a resilient network with multiple diverse routes. SC connections were used throughout the network as these have proven to be very cost effective where space is not an issue.

New basket trays were installed throughout the roof and service voids on each floor of the main building, above false ceilings in North Wing, South Wing and in any other buildings where large concentrations of

Cat 6 cable had been routed. New PVC surface trunking of varying sizes was installed around classrooms, offices and other areas requiring surface mounted containment. Sizing of the trunking was dependant on the amount of cables installed in any particular area. Care was taken to ensure that physical separation between power and data cables was kept as great as practically possible in order to minimise the risk of any electromagnetic interference (EMI).

The labelling scheme was based around the ANSI/TIA/EIA 606-A 2002 standard. All floor outlets, horizontal patch panels, cross connect patch panels and fibre patch panels were labelled using engraved, self adhesive labels that are resistant to aging and are highly visible. The use of such a high number of wiring centres necessitated a complex outlet numbering scheme that referenced the building, floor, wiring centre, patch panel and port that it is connected to. Each fibre optic link patch panel was labelled with the source-wiring centre reference and the core count of the presented fibre optic cable. Different coloured backgrounds to the engraved labels were used to differentiate between the different services and cable types.

The completed copper installation was tested for compliance to TIA/EIA Cat 6 Permanent Link. Fibre links were tested using an Optical Time Domain Reflectometer (OTDR) bi-directionally at 850nm and 1300nm wavelengths for multimode fibres. Singlemode fibre links were bi-directionally tested at 1310nm and 1550nm wavelengths.

The University decided to standardise on 3m Brand-Rex SMARTPatch cords at the wiring centres in order to reduce the inventory of cords held. For the same reason they decided to standardise on 5m fly leads to connect from the floor outlets to the terminal equipment.

The project presented a number of challenges, not least of which was the number of different types of area, with differing access constraints that had to be cabled. These included lecture theatres, classrooms, computer suites, laboratories and the library and involved a number of different types of building construction. The project plan also had to accommodate a number of department relocations and new building work schedules, for example the opening of the new Aston Academy of Life Sciences. Another part of the project involved the refurbishment and extension of Nelson building to provide a new conference centre, complete with two lecture theatres and accommodation for visiting delegates. Each of the seating positions in the lecture theatres was provided with a data outlet in order to facilitate interactive learning and each of the bedrooms was provided with at least two Cat 6 outlets. Access to laboratory areas had to be strictly controlled to ensure that Electron’s engineers were not put at any risk from ongoing experiments using toxic or volatile substances.

In the computer suites the desks were arranged in parallel rows extending out from the wall on which the horizontal cables were routed. Each of the desks was fitted with its own Cat 6 outlets but the issue was how to get the cables from the wall to the desk outlet. Electron came up with the solution of routing the cables from the wall-mounted trunking through flexible conduit in to the containment mounted along the rear of the desks, on to which the desk outlets were fitted.

Much of the cabling work was performed during term time and was carried out over night in order to minimise the disruption to lecturers and students. The work to install cabling in the larger computer suites was run to a separate timetable that demanded that the work be completed over the Easter vacation. Dennis Mottram said “Electron were very flexible in meeting the diverse needs of the mixed University environment whilst minimising the impact of the work of staff and students alike.”

At the end of the cabling installation Aston University were presented with a CD-ROM containing comprehensive documentation for the work carried out, all of which can be read using an internet browser. The documentation includes an overview of the work carried out, product datasheets, CAD drawings, wiring schemes, summary and detailed test results and wiring centre layouts, with separate sections for each floor or building. All of this means that the university will have ready access to all of the relevant information, thus minimising the delay in tracking down any particular detail. Dennis Mottram was also presented with a certificate from Brand-Rex by Simon Rhodes confirming that the completed installation is covered by a 25 year system performance warranty.

The infrastructure now supports multiple links of 4Gbps (10Gbps in the future) between the network nodes and 1Gbps to the Wiring Centres. The network that Damovo have delivered to the university is fully converged providing VOIP and IPTV as well as the LAN services. All telephone handsets are powered over the network (Power over Ethernet) and are protected by the network Uninterruptible Power Supplies (UPS), thus ensuring continuity of service in the event of a power failure.

Aston University’s new converged network has been named AstonIP and is currently the largest converged ICT network in the UK Higher Education sector. AstonIP brings together data, telephony and video onto a single infrastructure, with capacity and capability to meet the growing demands of a modern University. In September 2005 the project and Dennis Mottram were presented with the Communications in Business Award for Outstanding Achievement, Best Networking Project (Corporate) and Best Converged Network Project at the Communications in Business Award ceremony, sponsored by Communications News and Cable & Wireless.

Commenting on the completed installation Dennis Mottram said “The implementation of a Cat 6 cabling system had its challenges, particularly with regard to space for cables in containment and for patching in wiring centres, requiring innovative solutions and Electron’s design expertise. The Brand-Rex solution promises a flexible structured cabling solution with longevity and capacity for the growing needs of our users in addition to the improved administration achievable through the intelligent patching. We are delighted that the project has received the Communications in Business Awards and thank Damovo and Electron for their professionalism and dedication throughout this mammoth project”.

Click here to view the PDF file associated with this story.